Screen Printing

Brand Yourself

Screen printed T-shirts,

sweatshirts, team jerseys,

sweatpants, aprons, onesies, any and all textiles.

Screen Printing

We have manual presses, including one four station press and one six station press.

We do all work in our shop in Ridgefield, Connecticut.

Welcome to Our Press Room

Screen Printing: Brand Yourself or Your Team

Simply put, screen printing is a process of pushing ink through a stencil on a mesh screen in order to create an image. It is the standard for decorating apparel. Our customers use screen printing on various garments and items for company identification, team jerseys, spirit wear, fund raisers, reunions, or community events.

Efficent and Economical Way to Showcase Your Identity

Costs in screen printing include artwork, screen preparation, and the actual printing. Each color in the image requires its own screen: if the design has 4 colors, there will be 4 screens to complete the image. Each screen is printed separately. This makes multi-color designs more expensive than simple one-color designs. Screen printing is an efficient and economical way to decorate apparel especially when the design is one color and is being printed on 12 or more pieces.

Start with Vector Artwork Created in Our Shop or Provided by You

All printing processes start with the artwork. Crisp screen prints on garments need vector artwork. Our art department can create vector art as well as convert high resolution images to vector art. The converted artwork can be edited and sized for various uses with no change in the clarity. Film positives are created for each color in the design and then used to create the screens for printing. That small image one finds on the internet that blurs when enlarged is a bitmap (jpeg, png), not vector art.

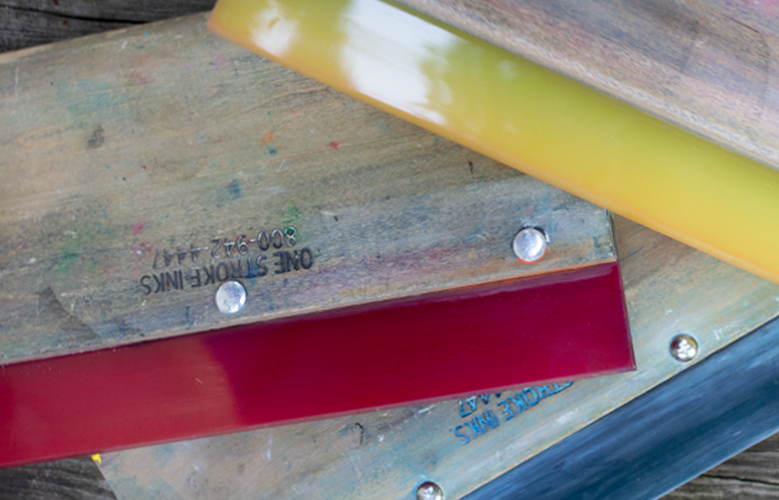

Preparing the Screens for the Press

Screens are prepared for the art by stretching a polyester mesh onto a frame. The mesh is then tightened so that there is a smooth surface on which to apply the light sensitive capillary film. First the artwork, next the film positive, and now the final step for the press. The screen with the film positive must be exposed and “washed out”, which means now the design has become a stencil and is ready for printing at the press.

Endless Options

The screen is aligned on the platform at the press and the selected color and style of ink is put onto the screen. There are a wide variety of ink colors available: stock colors and pantone matched colors. The garment is loaded onto the press, printed, placed in on the dryer belt, and once properly cured is ready to wear!

Our shop is a manual shop...we do it all by hand.

Screen Printing: Economical & Efficient

Great for community events, athletic teams, fund raisers, reunions, any group wanting a unique and personal garment.